All about Sheroz Earthworks

All about Sheroz Earthworks

Blog Article

Rumored Buzz on Sheroz Earthworks

Table of ContentsSheroz Earthworks Can Be Fun For EveryoneWhat Does Sheroz Earthworks Mean?Sheroz Earthworks for Beginners8 Simple Techniques For Sheroz EarthworksSee This Report on Sheroz Earthworks

For any kind of earthwork professional, it is vital to do work with quality, precision, and on time. Utilizing equipment control in job makers makes it possible for enhancing the different stages in the earthwork procedure, from preparing to the maintenance stage - topcon laser levels. The machine control system helps the machine operator in attaining the target aircraft rapidly and easily

The machine control system guides the driver with centimeter accuracy. Remote support conserves time and money, as it decreases downtime in jobsites.

Unknown Facts About Sheroz Earthworks

Our system's parts are very carefully developed to endure the rough conditions of construction sites. Contrast of the very same task carried out making use of machine control versus the traditional technique exposes that, on standard, the conventional method needs 50% more time to achieve the same job as the technology-assisted approach.

Seems excellent, right? Enter the Xsite device control system; it's below to supply you with a significant advantage when collaborating with earthmoving machinery. Discover exactly how Xsite Maker Control can boost your productivity and ensure job safety! We recognize that learning a new technology might seem like a drag, but don't fret! Our friendly and expert regional assistance solutions have actually got you covered, making sure that you can maintain functioning smarter without disturbances while at work! With remote assistance, your regional Xsite dealership can use guidance or troubleshooting without needing to visit the website! What sort of excavators does device control fit? Xsite Maker Control systems can be set up to any kind of excavator from mini excavators to big mining excavators.

How does maker control work? In 2D systems, the equipment is equipped with adjusted inclination sensing units. These sensing units are mounted on the pre-determined parts of the equipment in excavators the sensor are normally mounted to the structure, boom (or booms), digger arm and to the quick coupler - topcon laser levels. By using the data obtained from these sensing units the system can compute the specific position of the excavators container tip in relevance to a recommendation point.

The system is really easy to discover the fundamentals can be educated in under one hour of training. How does the remote assistance job? A wireless web connection makes it possible to develop a remote connection between the maker control system and the service.

7 Simple Techniques For Sheroz Earthworks

What sort of information styles Xsite systems assistance? Xsite Machine Control systems support open typical file formats, enabling seamless information flow from one system to one more. Sustained documents formats: 2D-Maps: DXF Factor data: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Area Models: DXF, XML What parts are mounted on my maker? Depending on your option of system (with or without placing, i.e - trimble repair parts., 2D or 3D), your equipment is outfitted with disposition sensing units, a controller system, and a display/operating panel.

Several equipment and software application remedies exist to help establish an equipment's current position on the planet and contrast it with a preferred layout surfaceand construction drivers can do more to leverage the advantages. Equipment control is the usage of various positioning sensing units and a display screen to offer the operator with a reference in between the setting of the container or blade and the target quality.

Depending upon the arrangement, maker control systems can supply the driver with a basic visual overview to bucket or blade placement, more info here or can immediately relocate the blade to grade by speaking with the equipment's hydraulics - https://lwccareers.lindsey.edu/profiles/5240299-floyd-overbeck. There are equipment control systems readily available for nearly any type of maker: graders, dozers, excavators, soil and asphalt compactors, scrapers, trimmers, milling devices, and pavers

Sheroz Earthworks Can Be Fun For Anyone

Some benefits include reduced rework, improved work performance, and reduced checking costs. Device control can also aid boost efficiency and reduce total expenses. This innovation is altering the way the building and construction market works. Building and construction devices without maker control will come to be a distant memory and the advantages acquired from it will be many.

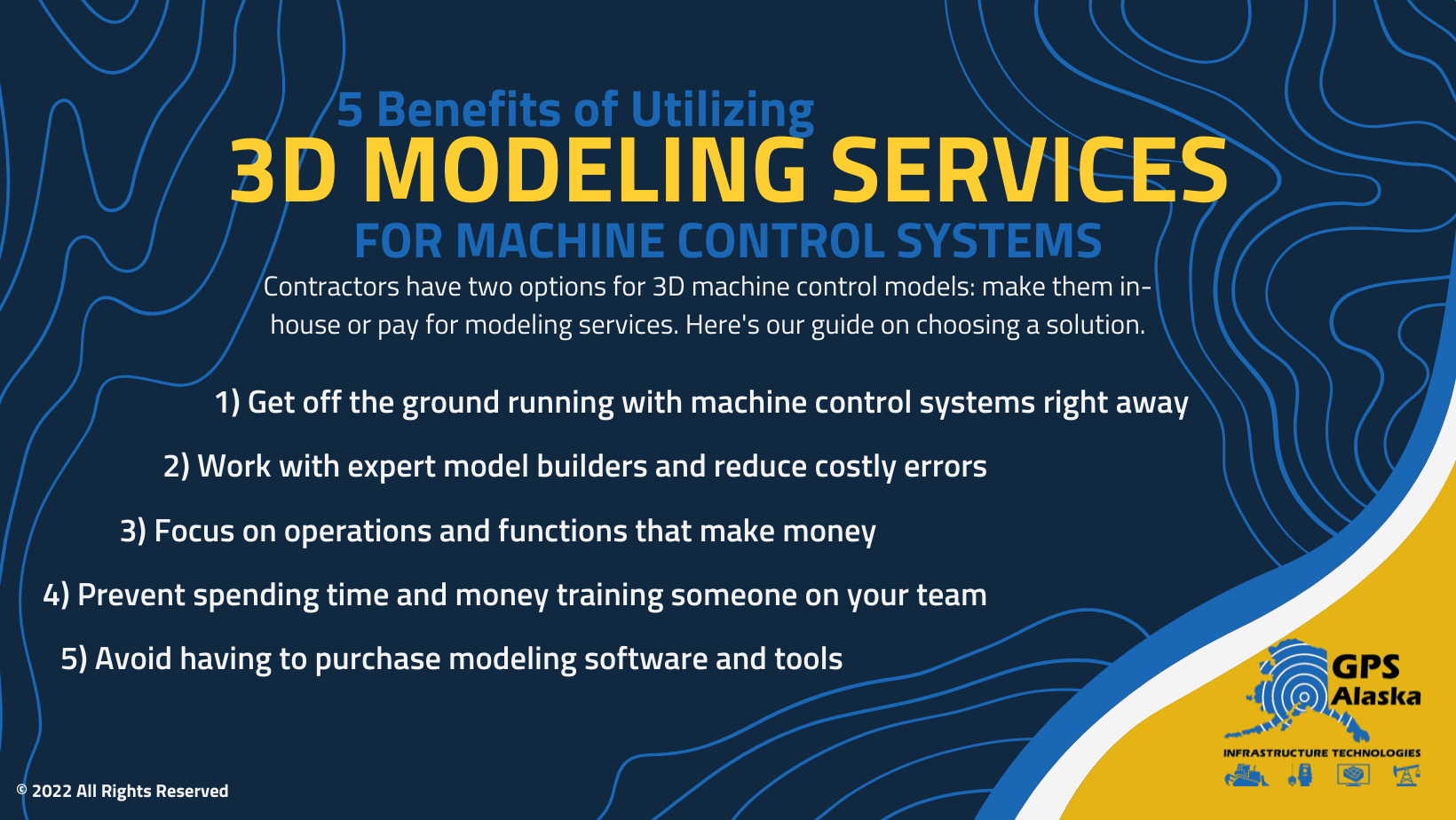

Trimble equipment control systems give a myriad of benefits to any person who makes use of earthwork machinery and, at EarthCalc, we can supply you with 3D data for your equipment control-enable tools. Uncertain if device control is worth the cost? Consider the adhering to reasons that you require to consider this option.

Utilizing GPS straightened with your 3D layout data, these systems practically guarantee that you will eliminate or place the correct quantity of material at the construction website. On a lot of building sites, rework is an usual and aggravating truth, however with Trimble equipment control, you can eliminate the need for rework.

Little Known Questions About Sheroz Earthworks.

Often, with Trimble maker control, you can remove excess equipment at a certain work site. For example, a work that might have needed making use of three or four items of digging deep into equipment currently might need just 2 tools to complete the exact same job in less time. This allows you to relocate your tools to another task site and take care of several tasks at one time.

Report this page